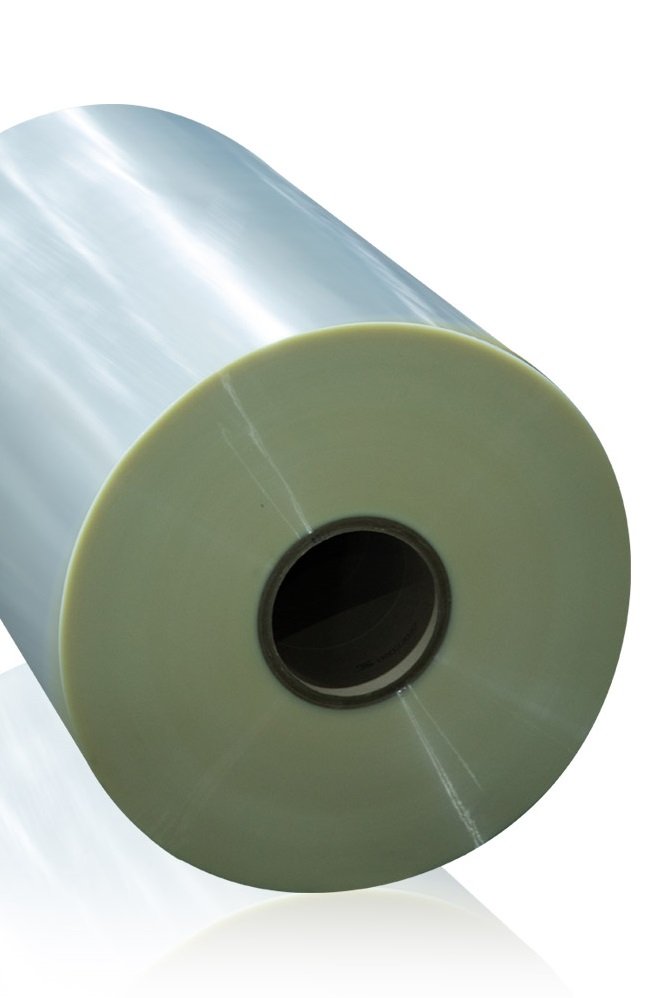

BOPA Film

BOPA Film Wholesaler (Biaxially Oriented Polyamide) , widely known as nylon film, delivers exceptional strength, durability, and barrier protection for advanced flexible packaging needs.

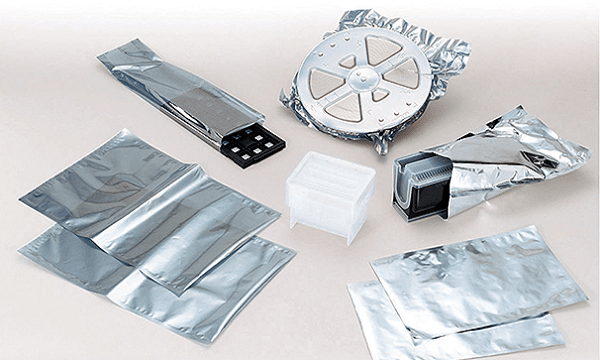

RH Enterprises specializes in high-quality BOPA base films and custom multilayer laminate structures including PA/PE and PE/PA/PE, engineered for vacuum sealing, retort packaging, frozen foods, and high-value product protection as a reliable BOPA Film Trader.

Why Choose BOPA Film

Outstanding Strength & Durability

Designed to withstand puncture, abrasion, and repeated flexing, making it ideal for meat, seafood, cheese, and bone-in products.

Advanced Oxygen & Aroma Protection

Minimizes gas transmission to preserve freshness, flavor, and product integrity over extended shelf life.

Crystal-Clear Appearance & Print Performance

Excellent optical clarity and surface quality support high-definition printing and premium brand presentation.

Reliable Performance Across Temperatures

Maintains stability from ultra-low freezing conditions to hot-fill and retort processes when laminated with compatible materials.

Excellent Bonding in Multilayer Structures

Compatible with PE, CPP, PET, aluminum foil, and EVOH, enabling high-barrier, customized flexible packaging solutions.

BOPA Film Series

Its high clarity, gloss, and surface smoothness enhance shelf appeal, while strong chemical and thermal stability ensure consistent performance across demanding processing and storage conditions. These advantages make BOPA film a trusted solution for food packaging, pharmaceutical protection, and industrial applications, making it a preferred choice for every reliable BOPA Film Wholesaler.